The urban micromobility scene has been growing at around 18% each year since 2020 according to the Urban Transport Institute report from 2023. Most of this growth comes from those shared scooter programs popping up everywhere plus all the last mile delivery folks zipping around cities. What this means in practice is that there's now a huge demand for scooter tires that can actually survive what city streets throw at them. Potholes, curb jumps, and just plain old constant riding wear these things down fast. Fleet managers tell us their shared scooters go through tires three times quicker than what regular people experience with their own rides, so they're really focused on getting those puncture proof designs to cut down on replacements. Airless tires used to be the big thing in places like Southeast Asia because they lasted longer, but riders want something different now. There's definitely a trend developing where people aren't willing to sacrifice comfort for pure toughness anymore.

Solid tires won't go flat because they're made from thick rubber, but there's a downside. They actually send about three times as much road vibration into the scooter frame compared to regular tubeless tires according to research published last year in the Micro-Mobility Engineering Journal. All that extra shaking wears out parts faster and creates safety problems too. A study back in 2023 showed that scooters with solid tires ended up in accidents 22 percent more often when roads were wet simply because they don't stick to surfaces as well. Tubeless tires work differently though. The air inside can be adjusted between roughly 20 to 50 pounds per square inch which helps soak up bumps. Riders who spend long hours delivering packages report feeling significantly less tired after switching to these models, with some studies suggesting fatigue drops by around 34% over those marathon shifts.

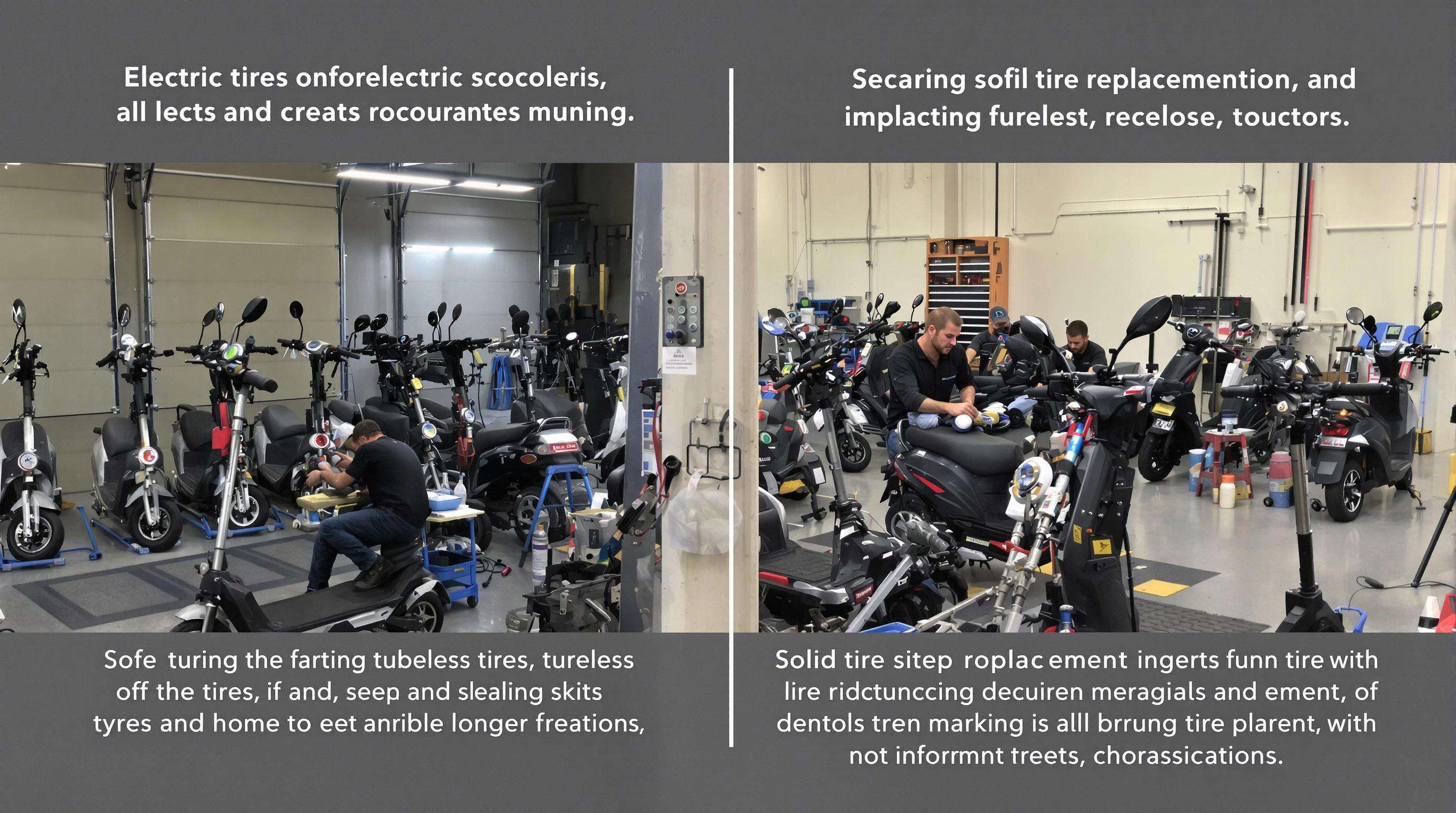

Around two thirds of fleet managers are going with tubeless tires when they deploy new scooters these days. The numbers show why too – downtime costs drop by about 40% compared to those old solid tire models according to the latest Global Fleet Operations Report from 2024. Take a look at what's happening across Europe. Cities such as Berlin and Barcelona have already adopted tubeless systems in about 60% of their shared scooter fleets. These systems last anywhere between 8 to 12 months generally speaking while still providing decent ride comfort. What's really pushing this trend forward? Manufacturers keep coming out with new foam sealed tubeless options that mix air cushioning with puncture proof liners inside. This solves many of the past maintenance headaches without making riders sacrifice anything in terms of how well the scooters perform overall.

Tubeless tires for scooter use pressurized air to absorb 30â40% more road vibrations than solid alternatives, according to the Transportation Research Board (2023). This air-cushion design enables:

Fleet operators report 27% fewer accident claims after switching from solid to tubeless tires for shared e-scooters, a shift attributed to improved grip and more predictable handling.

While maintenance-free, solid tires transmit 92% of road vibrations directly to handlebarsâa key reason for their 4.2/10 rider comfort score (Micromobility Benchmark Report 2023). Hard rubber compounds also:

The European Transport Safety Council notes solid-tire scooters account for 61% of vibration-related mechanical failures in bike lane environments, underscoring long-term reliability concerns.

| Factor | Tubeless Tires | Solid Tires |

|---|---|---|

| Vibration Dampening | 8.7/10 (Air Pressure) | 2.1/10 (Rigid) |

| Cornering Stability | 15° lean angle capacity | 9° maximum safe lean |

| Speed Stability | Maintains control up to 28 mph | Wobbles emerge at 19 mph |

Airtight tubeless designs maintain consistent performance across temperature fluctuations, while solid tires become 23% harder in sub-50°F conditionsâcompromising both comfort and control.

Tubeless tires work by using liquid sealants that can fix small punctures up to about 3mm in size, which cuts down sudden flats by around two thirds when compared with regular air-filled tires according to Urban Mobility Analytics from last year. Still, these tires aren't perfect either since their sides can tear pretty easily if someone hits a curb or runs over some big road debris. Then there are solid tires that never go flat at all, but they come with their own problems. They transmit vibrations much more than normal tires do, roughly forty percent more actually, and this extra shaking tends to wear out the frames of those shared electric scooters much faster especially when riding across rough city streets where pavement isn't so smooth.

Looking at fleet data shows that solid tires last about 15 percent longer than regular ones, clocking around 1,200 miles compared to just 1,042 before needing replacement. However there's a tradeoff here since these same solid tires cause roughly 2.3 times as many motor mount problems because of all the extra vibration they create. Now when it comes to tubeless systems, they tend to hold their grip pretty well for about 800 to 1,000 miles on average. The catch though is that drivers need to check tire pressure every month or so to prevent early wear caused by being too low. This becomes especially important in urban areas where most streets are made of concrete, which makes up over three quarters of road surfaces in many major cities across the country.

Solid tires do cut down on those annoying flat tire situations, but according to fleet managers across the country, they actually end up costing about 22 percent more in maintenance expenses after just 18 months when compared with regular tubeless tires. What makes this happen? Well, because these solid rubber tires don't absorb shocks very well at all, bearings need replacing roughly three times more often each year for vehicles running eight hours or more per day. So bottom line here is that solid tires make sense economically only in certain niche markets like low speed equipment rentals where getting things fixed quickly matters more than lasting forever.

Solid tires eliminate puncture repairs but require full replacements every 12â18 months in high-use environments, averaging 45 minutes per swap. Tubeless alternatives need monthly pressure checks and sealant replenishment (5â10 minutes per scooter) but reduce downtime by 72% compared to solid tire replacements. This creates a clear operational advantage:

| Maintenance Factor | Solid Tires | Tubeless Tires |

|---|---|---|

| Annual Labor Hours | 3.2 hr/scooter | 1.8 hr/scooter |

| Downtime Cost/Incident | $18.50 (IDC 2023) | $4.20 (IDC 2023) |

Shared mobility providers report a $217/scooter/year Total Cost of Ownership (TCO) gap favoring tubeless designs. A 2024 analysis of 23,000 e-scooters showed:

Distributors must stock three critical components to support tubeless scooter tires:

Preventive maintenance contracts covering these items reduce fleet operator TCO by 19% compared to reactive repair models.

Solid tires are made of thick rubber that prevents flats but transmits more road vibrations, leading to quicker wear of scooter components. Tubeless tires use air cushioning to absorb vibrations, providing more comfort and better road grip.

Tubeless tires reduce downtime costs and enhance ride comfort, decreasing fatigue and improving rider safety. Fleet operators report fewer claims related to accidents after switching to tubeless designs.

Tubeless designs offer better wet-surface traction, reducing stopping distances and enhancing overall ride stability. This results in fewer accidents and mechanical failures.

While solid tires reduce the risk of flats, they lead to higher maintenance costs due to increased vibration and wear on scooter parts. They may be economical only in specific low-speed rental scenarios.

Tubeless tires need regular pressure checks, sealant replenishments, and rim inspections. Preventive maintenance helps lower total cost of ownership compared to reactive repair practices.

Hot News

Hot News

© Copyright 2024 Shenzhen New Image technology Co., Ltd All Rights Reserved Privacy policy